What is difference between a waffle pod and Cupolex concrete slabs?

What are waffle Pods?

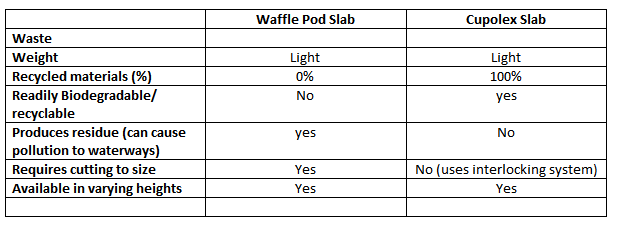

Waffle slabs are a reinforced concrete footing and slab system constructed on the ground. Waffle pods are used to create voids between the strip footing and create airflow under the slab. Waffle pods are made from polystyrene which are lightweight but also bulky. Difficult to store onsite and often leaves residue that can contaminate our waterways and excess pods and offcuts often ends up in land fill. Due to the components that make up polystyrene unfortunately, the pods do not readily biodegrade making them a poor choice in terms of sustainability for the building industry. Waffle pod slabs are designed to comply with the National Construction Code (NCC) AS2870 for residential slabs and footings. A qualified structural engineer is required to

What is Cupolex?

Cupolex has been introduced as an alternative solution to a waffle pod or raft slab. The Cupolex system utilises interlocking dome structures to create void form concrete slab foundations. Cupolex is also more environmentally friendly, made from 100% recycled and recyclable nontoxic materials. Unlike polystyrene there is no risk of residue ending up in waterways. The air cavity underneath the Cupolex domes resists mould and mildew for a healthier work environment. Cupolex could also reduce the amount of concrete and steel mesh required for the concrete slab making it a great solution for reducing materials and cost for the builder. Cupolex is also fast to install and light weight. Due to the interlocking nature of the Cupolex system is fast to install eliminating messy offcuts onsite and saving time. The arches of the Cupolex domes make the slab stronger by putting the concrete under compression rather than tension to distribute live loads across a larger area than slabs on grade.

What’s the difference between using waffle pods vs the Cupolex system?

Why use Cupolex as an alternative to waffle pod or raft slab?

Cupolex could be a great alternative for your structural concrete slab formwork for its environmental benefits as well as time saving and possible cost saving benefits to the builder. Cupolex is engineered by qualified structural engineers, the same as any other structural concrete slab type. The compliance of a Cupolex concrete slab comes under the relevant Australian standard AS4859. 1: 2002. The system could reduce the amount of steel and concrete required. In addition, Cupolex has some fantastic time saving benefits, that could ultimately reduce the overall cos of the build. Cupolex is easier to transport than polystyrene and easier to store onsite. Cupolex is stacked neatly on pallets. Polystyrene takes up a lot more space and requires holding down to prevent it blowing away in the wind when it’s being stored onsite. In terms of labour, around 150-200m2 of Cupolex can be installed per hour with just 2 people, this is because the interlocking system makes it fast to install, eliminating the need to cut the product to size and reducing waste. These are just a few benefits of saving time and potentially reducing costs over the lifespan of the build.

Contact us to learn more about Cupolex and how it could be an alternative option for concrete slab formwork. Cupolex is available from Enviro Slab along with engineering support to assist you through the process.